DEMAGNETIZING

A lot of machined parts have to be absolutely free of magnetism because of their intended use.

If materials or tools are magnetized, there may be negative effects, e.g.:

• sticking steel chips or grinding dust

• assembly problems

• blow effects which complicate the welding process or lead to faulty weld seams

• sticking parts in collecting tanks or on machine parts

• premature wear of components due to sticking microparticles, e.g. in bearings and gears

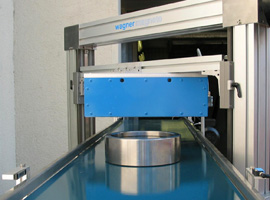

Wagner Magnete has accumulated rich experience in this industry. The customized design can achieve the best effect of demagnetization. It can be used for automatic assembly line demagnetization and individual demagnetization of individual components.

Welcome to call our company to provide professional solutions according to special requirements.

Please contact our representative for more information.

Worldwide :

please contact the head office: